Company Information

Outline

History

Production

□Company Outline

Company Name Bihoku Funka Kogyo Co.,Ltd. |

|---|

Board Directors President :Shiro Miyata |

| Executive Vice President : Yoshiteru Watanabe |

| Director : Akihiro Shimohashi |

| Director :Yasunori Tanabe |

| Director : Hiroshi Matsumoto |

| Director : Yoshiki Togo |

| Director : Koji Watanabe |

| Auditor : Koji Miyata |

| Auditor : Reiko Fujii |

Established anuary 1, 1942 |

Incorporated January 1, 1947 |

Offices Head Office / Niimi Plant704,Nishigata,Niimi City,Okayama 718-0017 TEL 0867-72-2158 / FAX 0867-72-7025 |

| Fukushima Plant 2-2,Dainichimae,Aza,Kamiogoe,Ogoemachi,Tamura City,Fukushima 963-4111 TEL 0247-79-2145 / FAX 0247-79-2146 |

| Tetta Plant 885,Hongo,Tettacho,Niimi City,Okayama 718-0303 TEL 0867-96-9025 / FAX 0867-96-9026 |

| Sales Department (Osaka Office) 1-6-8,Kitahorie,Nishi-ku,Osaka 550-0014 TEL 06-6534-0777 / FAX 06-6534-0788 |

Capital Authorized Capital Stock:¥35 million (700,000 shares)Paid-up Capital Stock:¥30 million (600,000 shares) |

Types of business Manufacturing and Selling heavy calcium carbonate for Industries, Pharmaceuticals, and Food Additives |

Number of Employees 156 |

Mine Karabitsu Mine1073,Hongo,Tettacho,Niimi City,Okayama 718-0303 TEL 0867-96-2445 / FAX 0867-96-2445 |

| Otakine Mine 140,Odaira,Aza,Kamiogoe, Ogoemachi,Tamura City,Fukushima 963-4111 TEL 0247-79-3636 / FAX 0247-79-3636 |

□Company History

1942

Bihoku Seifun Kogyosho estabilished.

Niimi Plant(No. 1) constructed. Yogai Mine developed.

1947

Changed the name to Bihoku Funka Kogyo Co., LTD as incorporated.

Capital: ¥2 million.

1949

Capital increased to ¥3 million. Osaka Sales Office opened.

1957

Succeeded in mass production of "SOFTON" ultra fine particles.

1962

Capital increased to ¥9 million.

1963

Capital increased to ¥15 million.

1964

Designated as a model plant for small business study by Okayama Prefectural Government.

1965

Niimi Plant(No. 2) constructed.

1966

Produced “LIGHTON”,surface coated superfine calcium carbonate.

1967

Capital increased to ¥19.5 million.

1968

Designated a model plant for rationalization of small businesses by the Small and Medium Enterprises Agency, Okayama.

Prefectural Government Awarded the Director-General's Prize by the Small and Medium Enterprises Agency.

1971

Certified Drag manufacturing license of Precipitated Calcium Carbonate Japanese Pharmacopoeia..

Designated as a model plant for rationalization of small businesses by the Small and Medium Enterprises Agency. (also designated six more times thereafter)

1972

Capital increased to ¥30 million. Fukushima Plant opened.

1984

Wet type grinders completed at Niimi Plant.

Released "HYDROCARB" wet-type calcium carbonate.

Dry type classifiers at Niimi Plant (No.1) underwent drastic overhaul.

1986

Receired the Hiroshima Bureau of the Ministry of International Trade and Industry by electrical safety.

1989

Wet type grinders completed at Fukushima Plant.

1990

Relocated manufacturing plant for Pharmaceuticals and Food Additives to Tettacho.

Updated Dragmanufacturing license.

1995

Karabitsu Mine developed. Material plant for the Mine completed.

New Head Office and Fukushima Plant office building completed.

1998

Released “μ-POWDER” new function calcium carbonate.

1999

Released “SETACARB HG” wet-type super fine calcium carbonate.

2002

Head Office, Niimi Plant, Karabitsu Mine and Osaka Sales Office obtained ISO 9001 (2000) certification.

2003

Fukushima Plant and Otakine Mine obtained ISO 9001 (2000) certification.

Tetta Plant certified and registered for GMP (Good Manufacturing Practices) for food additives.

Released “LIGHTON TC-5”, precision-classification ultra-fine particle calcium carbonate.

2004

Head Office, Niimi Plant, Tetta Plant, Osaka Sales Office and Karabitsu Mine obtained ISO 14001(2004) certification.

2005

Tetta Plant obtained ISO9001(2000) certification.

Fukushima Plant and Otakine Mine obtained ISO14001(2004) certification.

2007

Expansion of production facilities of “LIGHTON” in Fukushima plant.

2009

Expansion of production facilities of Wet type grinders in Fukushima plant.

2010

Completion of expansion of production facilities of Wet type grinders in Niimi plant.

2016

Tetta Plant obtained HALAL certification. (NPO Japan Halal Association)

2019

FSSC22000 Certified

□Production base

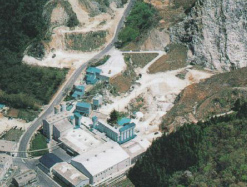

Niimi Plant

Main plant located in Niimi City, Okayama Prefecture. Karabitsu Mine is said to have 100 million tons of quality limestone reserves that will facilitate a stable product supply for the next 500 years.

ISO9001 and ISO14001 certified.

Fukushima Plant

Fukushima Plant in Tamura City, Fukushima Prefecture. Bihoku Funka Kogyo’s Niimi Plant in the West and Fukushima Plant in the East of Japan come together when necessary to further strengthen our already thorough product production system.

ISO9001 and ISO14001 certified.

Tetta Plant

Tetta Plant located alongside Karabitsu Mine is fully outfitted with a clean room capable of removing extremely fine dust particles and manufactures calcium carbonate for pharmaceuticals and food additives.

Drug manufacturing license / Food additives GMP certification

ISO9001 and ISO14001 certification.

HALAL certification. (NPO Japan Halal Association)

□Transportation and Packaging

Paper Bag

Can choose from 20kg, 25kg, 30kg bag sizes to suit individual needs.

Flexible Container Bag

Helps maintain quality while simplifying storage and management.

Advanced Tank Lorry

Delivery can also be made by tank lorry in accordance with customer needs.

| Privacy Policy |Japanese |

Copyright © 2018 BIHOKU FUNKA KOGYO CO.,LTD. All rights reserved.